Selecting, using, and caring for engineering dimensional measuring equipment

Baylie Raxworthy

132030449

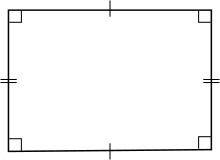

People credited with this unit standard are able to – select; use, and care for engineering dimensional measuring equipment.

Examples of engineering dimensional measuring equipment are – vernier callipers; internal, external, and depth micrometers; dial test indicator (DTI); height gauges; steel rules.

To pass this assessment I need to provide evidence that I can select the correct equipment in accordance with the geometry of the object to be measured, likely magnitude of dimensions, and required accuracy.

I also need to show that I can carry out equipment checks before use and any faults are reported, examples are – deformation, breakages, stickiness, not zeroing, missing parts, expired calibration.

My evidence to support my assessment booklet will need to show a micrometer; vernier callipers; and two other items of dimensional measuring equipment from the list above.

My evidence of using Dimensional measuring equipment.

What have I learnt?

I learnt how to use a variety of measuring tools for my project.What was the most difficult tool to use and why?

The micrometer was confusing to use because of how on point it has to be.What did I enjoy?

I enjoyed learning more about measuring devices that I could not use before.What would I do differently next time?

Use the micrometer more to measure my materials if I wanted an accurate answer.This supports the assessment for dimensional measuring equipment that can be found on this website https://sites.google.com/hornby.school.nz/mr-r-manufacturing/senior-manufactring/dimensional-measuring-tools?authuser=0

For more information on Competenz and starting an apprenticeship follow this link: www.competenz.org.nz/jobseekers/